FIELDS OF APPLICATION

Refrigeration

For over 20 years we have devoted ourselves to the production of thermoformed accessories used in the refrigeration sector. We have an internal department specialised in polyurethane foaming with water-blown isocyanide and polyhydric alcohol, thus making a low environmental impact.

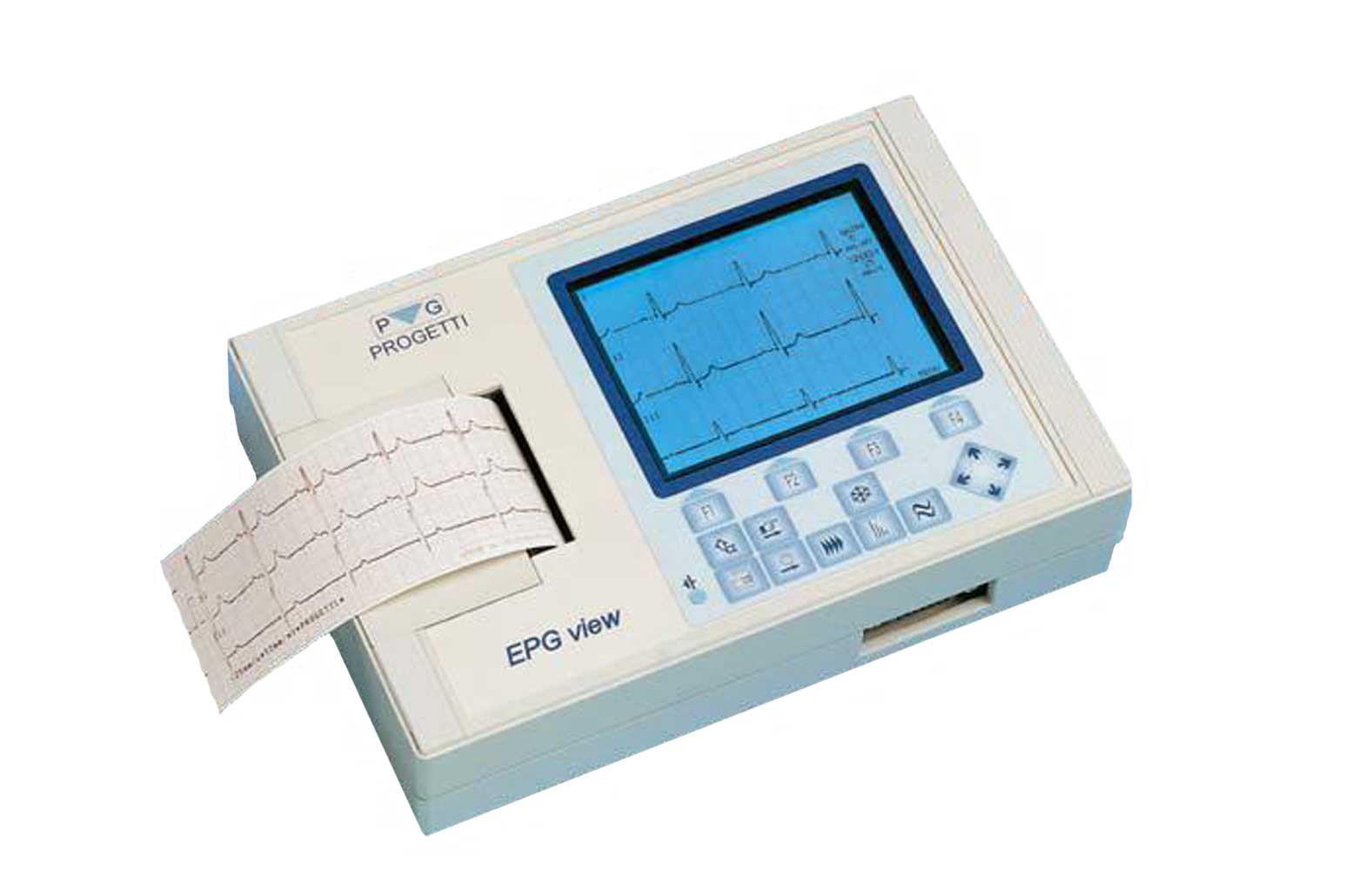

Medical field

- antimicrobial

- antibacterial

- antimycotic

- anti-algae.

Visual Communication

We make thermoformed components for backlit advertising signs and pop-ups that can be placed in coffee bars, supermarkets, public places of business and venues where there is a high visitor attendance. We process all types of material, from PMMA to opaline materials, with the possibility to apply any company logo, drawing or blazon.

Sanitary Fixtures and Bathroom Furnishings

Thermoformed materials and components are also widely used in the bathroom furnishings sector: from bath tubs to shower cubicles with walls equipped for alternating hot & cold shower or hydromassage. The material generally used for these components is ABS+PMMA. We use high density polyurethane foaming in our production cycle as it allows us to provide the shower tray and walls with the technical characteristics necessary for their functions.

Interior furnishings and exhibition design

The other main road in which thermoforming is widely applied is furnishings, across the board: from lighting – for both the public and private sectors – starting from materials such as self-extinguishing polycarbonate or PMMA to that for building trade fair stands, shops and showcases.